- sous-vide

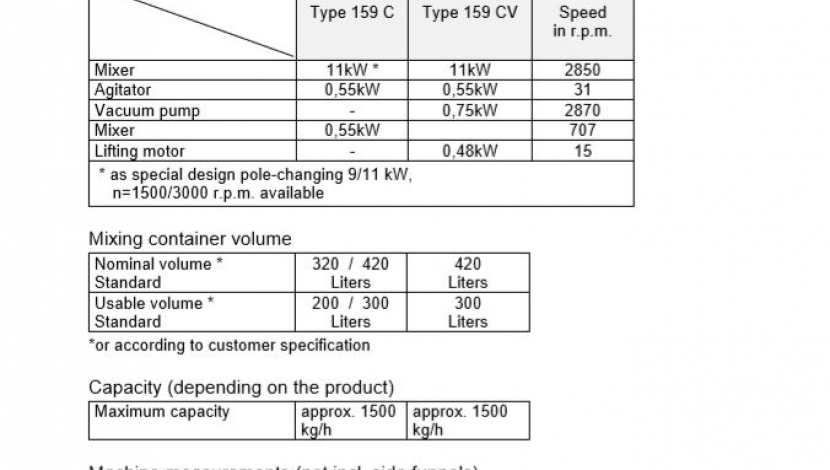

- 11,75 kW

- cuve 420L

- charges de 300L

- vitesse de transfert (eau) 500L/min.

- moteur principal capacité homogénéisateur 11 kW

- pompe à vide capacité 0,75 kW

- table de mixage avec racleurs sur le côté et le bas 0,55 kW

- contrôle PLC Touch (Siemens)

- dimensions (lo x la x h) : ± 2.100 x 1.500 x 2.400 mm

- installation apter pour la production de vinaigrette, mayonnaise et ketchup

+

réservoir d’ingrédients

- 200 l avec agitateur papillon 1,1 kW

- racleurs sur bas et côté 0,37 kW

- diamètre : ± 850 x 1 800 mm

+

réservoir d’ingrédients

- 200 l avec agitateur papillon 1,1 kW

- diamètre : ± 850 x 1 800 mm

Un contrôle PLC supplémentaire est inclus pour synchroniser les réservoirs d’ ingrédients et le homogénéisateur, avec des vannes et des compteurs liquides.

This machine is highly suited for the production of homogeneous and dispersion products. The new mixing unit with the designation 159 permits the production, in one work process, of a homogeneous basic substance, into which lumpy products can be subsequently stirred. A powered adjustment unit makes it possible to switch off the homogenizing station; the product is gently circulated, and lumpy product parts can be added and stirred without the use of additional paddle mix containers. The machines are thus suitable for the mixing, stirring, dispersing and homogenizing of liquid, viscous and, even, strongly viscous products. Consequently, mayonnaises of all quality grades, ketchups, spicy sauces, dressings, emulsions, dips, remoulades, soups and other products can be manufactured. For the processing of homogeneous products the machines are supplied without an adjustment unit. The individual ingredients are added either directly into the mixing container or by means of a side funnel. Connections, which make a direct filling of the machine possible, are available. Until it reaches the desired consistency, the product circulates between the mixing container and the mixing unit and then the final product is pumped out of the machine.

In this case, the homogenizing process takes place under vacuum conditions; the product is thereby continuously vented and thus has a longer durability and is protected against oxidation and discoloration. For cleaning purposes, the mixing container can be separated from the mixing unit, so that all parts which come into contact with the product can be reached quickly and easily. A bearing plate completely separates the drive from the mixing area.