Second hand industrial cookers

Barsso buys and sells pre-owned machinery for the food processing industry. We offer you a wide range of second hand industrial cookers or cooking vessels. Our used cooking vessels can be heated by indirect steam or thermal oil. We offer you second hand cooking kettles, tillable kettles and horizontal agitator systems with Teflon wall scrapers, but also impingement ovens, travelling ovens and convection ovens.

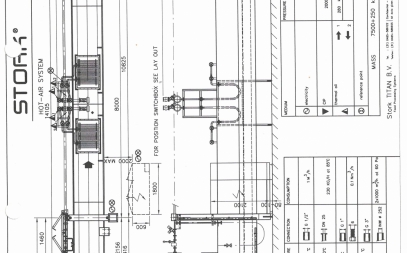

Hot air oven or belt oven

The hot air oven is a belt oven for continuously preparing food products. It comprises a housing and a conveyor belt which is movable through the housing and on which the food products can be arranged. The heating elements and booster devices generate a stream of hot air through the housing while heating the food products arranged on the belt.

In the housing, there are elements to guide the stream of hot air over the belt in such a way that the products are uniformly heated in the transverse direction of the belt.

Belt ovens are mainly used to cook of all kinds of meat, poultry and fish products. Achieving the right appearance, flavor and texture for the most satisfying experience: it all depends on the cooking parameters. With heat treatment solutions you can control the process for the desired degree of juiciness, crispiness and browning.

Would you like more information on our different types of second hand industrial cookers? Or would you like a price quote? Contact us!

-

-

-

Cooking system “Schomaker” Type WKS 6000/1250 + Pre cooling system (sprinkling water) “Schomaker” Type SVKB 5000/1200

steam heated

Siemens control unit

teaserlink -

“FlowCook” Hot air oven “GEA-CFS” Type FLC 8000/600

electrically heated, 180 kW

with CIP cleaning system

teaserlink -

-

-

-

-

“FlowCook” Hot air oven “GEA-CFS”, Type FLC 14000/600

belt width 600 mm

belt length 13.000 mm

teaserlink -

Universal smoking system – baking and cooking chambers “Fessmann” - “Maurer”

smoking system

baking and cooking chambers

teaserlink -

Linear oven 3 tiers “Provisur TST”, Type COO1350x6000

belt width ± 1.350 mm

3 tiers from 6.000 mm

teaserlink -

-

Sold

Hot air oven “GEA-CFS”, Type HLT 6000/600

canopy with electric hoists

electrically heated

teaserlink -

Sold

-

Sold

-

Sold

-

Sold

Process vessel "Berief" with stirring system, Type Kippko 400

Suitable for steam heating

double jacket

teaserlink -

Sold

-

Sold

-

Sold

-

Sold

Process vessel “Gernal” with stirring system Type KKK-5-DW-R-PLC-500

tiltable drum

capacity 500 L.

teaserlink -

Sold

Jet Stream® linear impingement oven “Stein”, Type JSO-IV-40-22TF

belt width ± 1.000 mm

automated clean in place syste

teaserlink -

Sold

-

Sold

-

Sold

-

Sold

-

Sold

CookStar “GEA-CFS” Spiral oven, Type HLS 1000/8/130-257

tiers : 2 x 4 pcs

suitable for thermic oil heati

teaserlink -

Sold

Hot air oven “GEA-CFS”, Type HLT 14000/1000-36 FlowCook

outfeed conveyor

belt washing system

teaserlink -

Sold

Industrial oven “GEA-CFS”, Type HLT 10000/1000

belt length ± 10.000 mm

belt width 1.000 mm

teaserlink -

Sold

Static Autoclave – Retort steam / air system “Lagarde”

with heat exchanger “Vicarb-S.

suitable for pre-cooling

teaserlink -

Sold

“GEA-CFS” Spiral oven “Cookstar” Turbo, Type TurboCook, CKH600/8/100-356

suitable for thermo oil heated

belt length: ± 60 m

teaserlink -

Sold

-

Sold

-

Sold

-

Sold

Autoclave - Retort “Steritech”, Type Steritech ST5-AST-AEH-PMG

suitable for 5 trolleys

with heat exchanger

teaserlink -

Sold

Super hot air steam cooker “TST Techniek - Provisur”, Type SHASC 8000/600

with belt wash system

PLC control

teaserlink -

Sold

-

Sold

Process vessel “Gernal” 500L with stirring system, Type MBK 500-S-PLC

suitable for steam heating

tiltable drum

teaserlink -

Sold

After Heating Tunnel 5 tiers “Wittkamp”

suitable for steam heating

infeed and outfeed conveyor

teaserlink -

Sold

-

Sold

Hot air oven "GEA-CFS", Type HLT 8000/1000

suitable for steam injection

belt washing system

teaserlink -

Sold

Process vessel - Vacutherm System “Stephan” 400L, Type V-MC 400/15

microcutter MCH15

capacity : ± 1.600L/h

teaserlink -

Sold

-

Sold

-

Sold