Molding line for filled products such as cordon bleu (fresh weight 100gr)

The fresh weight per portion is ± 100 grams. The main components are 48 grams of ground meat 10 grams of processed cheese 10 grams of sausage or ham the rest is breadcrumbs

consisting of:

“Risco Brevetti” vacuum filler

Type RS303 (filler-grinder)

- with loader for Eurobins

- with meat grinder heat (Filler-Grinder), Type RS 70

- BJ 2010

- filler-grinder opening 2 filling strips on top of each other of 90 x 5 mm

+

MasterSlice “Marel - Stork”

Type 1511

- Slicer for sausage or ham bars caliber 50 mm

+

“Karl Schnell” vacuum filler

Type 596 P 10 SE

- Used to fill the processed cheese linked to the Masterfill

+

“Marel” MasterFill

Type MTFU

- Takes the processed cheese from the Karl schnell vacuum filler and portion it

+

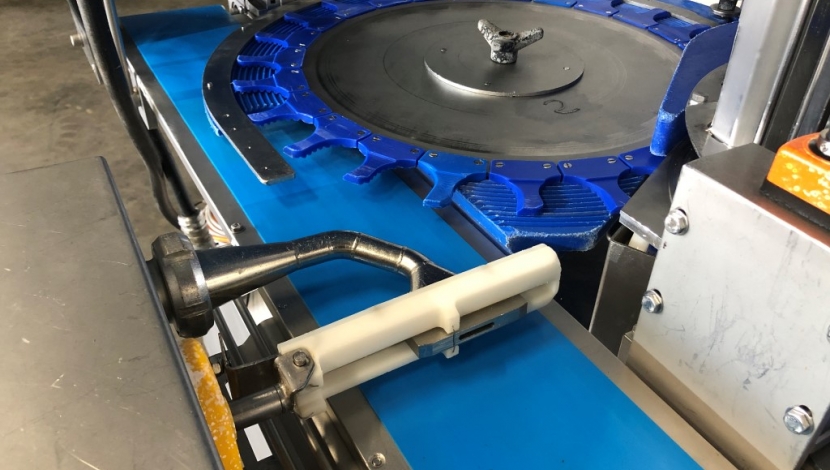

“Marel” MasterFormer

Type TA1521

Using virtually no pressure, the MasterFormer system produces high quality filled and unfilled products with a handmade look and retention of structure and texture of meat mass.

The MasterSlice and MasterFill modules allow solid, liquid and paste fillings to be added to the meat mass in the MasterFormer supply line.

The MasterFormer offers a wide variety of end product possibilities with minimal waste of ingredients and maximum flexibility, including cordon bleu or steak haché.

Features :

- Ultra low-pressure forming, to retain structure and texture of meat mass

- Fully automatic production of filled and unfilled products, with a handmade look

- MasterSlice adds cut-to-measure slices of solid filling to the basic raw material

- MasterFill is used to add liquid or paste fillings

- Minimal waste of ingredients

- End products can be packed directly onto trays or, alternatively, are ready for further processing

- Easy to operate and clean